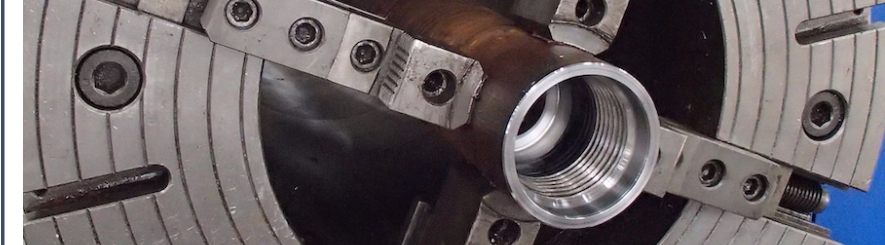

Machining

With a machine shop facility of 9,660 m², Algoa is unmatched in all of West Africa in the number of connections we're certified to cut, as well as the state-of-the-art machinery we have in our workshop.

With a machine shop facility of 9,660 m², Algoa is unmatched in all of West Africa in the number of connections we're certified to cut, as well as the state-of-the-art machinery we have in our workshop.

We offer the following manufacturing services:

- Bottom hole assembly tools; crossover subs, lift subs, pup joints, top drive saver subs, and lift nubbins;

- Orifice flanges and plates, spectacle blinds, paddle plates, and other flow measurement items;

- Drifts and rabbits, and other dimensional measurement items;

- Torque make-up and break-out operations.

Algoa provides API and premium tubular threading and repair services for a comprehensive range of drill pipe, casing and tubing:

- Tubulars: drill pipe, drill collars, heavy weight drill pipes, ARC collars, mongrels etc;

- Bottom hole assembly tools and accessories;

- Re-dressing and re-building of stabilizers;

- Re-work of casing and tubing connections, joints, pup joints, and torque float equipment assembly;

- Valve upgrades for actuator use;

- Gearbox repair;

- Repair and re-threading services for specialised tools such as Vetco running tools, mud line hangers etc.